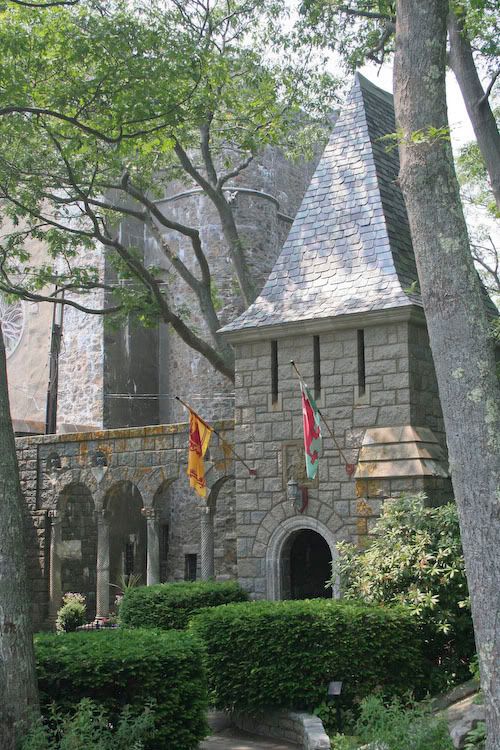

The castle construction was started in the mid-1920s and finished in 3 years to the tune of a half million dollars (around $4.5M today). I don't know if that includes the cost of obtaining and shipping all of the antiquities used by Hammond in the castle's construction. Incorporated into the castle's design were parts of Medieval buildings and antiquities from around the world; I saw everything from Byzantine-looking plaques and carvings to the entire shop fronts of original buildings. The whole thing has a rather slap-dash eclectic look to it, especially the main castle. I don't mean slap-dash as in poorly built, but sometimes as I viewed the structure I wondered about the lack of continuity, even in the space of the same wall! I suppose I can't fault the designers, when I design my castles in Sketchup, I'm always trying to mash more than one style into the works to make it more interesting. As far as the major styles of the castle, it was built with a "German" section, and a "French" section. Basically the older looking section with the great-hall, turrets and the like is the former, and attached to that is a chateau/castle building in the latter style.

The French themed building was very well done, quite neat and pretty on the exterior. You can't quite get a good view of it in the photos due to the trees and the inability to get far enough away to get it all in one shot. You can see similar buildings here to kind of get a feel for the look.

The interesting thing is that the Chateau is "hollow"; it's basically a square with rooms on the sea and street sides, hallways at the farthest end and attached to the castle great room at the other end. The interior of the hollow square is covered with a glass roof and has a pool and a very nice little courtyard. Facing the courtyard are two real Medieval shop fronts, what looks to be a Gothic church entrance and a Romanesque wall. This end of the castle has all of the bedrooms (at least the ones that were accessible to the public), the dining area, the kitchen and many of the normal-looking living areas of the castle. The kitchen is a mix of modern and old, obviously added to and re-done as time went by. In this end of the house there were sitting areas, a library, and offices (Hammond ran his business out of the castle for a while). The dining room was possibly authentic Medieval as well; if it wasn't, they did a great job making it look so. Also, one of the rooms apparently has tiles brought from Diego Columbus' (son of Christoper) home.

The main castle had lots of little passages, rooms and spiral staircases. It contains a chapel as well as what looked to be a small real Medieval armorer's shop and tools, and the castle armory. I think there were several rooms that were unavailable to the public in the castle, from the outside one could see rooms stuffed with objects that we didn't get to see, as well as many, many locked doors. The overall layout of the castle seemed pointless, there were small rooms scattered about that didn't seem to serve any purpose other than to hold the items collected by Hammond. They were too small to be functional and too difficult to get to for daily use. I get the feeling that the castle was more of a curiosity and novelty for Hammond's guests, but all real living was done in the Chateau.

Unfortunately, the dungeon was inaccessible to the public while we were there. I'm not sure when or if it is available for viewing. There is a photo of a rather realistic deceased dummy on the other side of a grated door in a dark passage in one of the photos, I assume this is one of the dungeon's access points.

One of the disappointing things about the castle was the fact that throughout the castle, new, "tacky" items have been added. There were modern resin gargoyles glued to the walls, cheap production swords from catalogs (I've looked at them in those very same catalogs), Thomas Kinkade prints on the walls. If I were younger, I'd be pretty excited at all the shiny, sharp pointy things hung on the walls. Now it just doesn't seem right.

My observations on the construction...

The buildings were constructed of poured concrete in many places, or concrete and stone where it had stone incorporated into the design. It's pretty random as far as what went where. The photos show some of the odd arrangement of materials. I think insulation was unheard of or unplanned for due to authenticity or it simply wasn't done with those materials back then. Our house was built just prior to 1900 and I don't think they had any insulation at all in the walls until someone cut holes in the exterior and blew some in. The castle's buildings have solid walls, meaning probably quite warm and humid in the summer and cold and clammy in the winter (just like the real thing, eh?). As a side note, the museum curator showed us on the B&W photo of the castle where the high tide line was today vs. where it was when the photo was taken. There was a 20-30 foot difference. Sinking earth or rising sea levels? You pick... Anyway, the castle was definitely lacking in windows and ventilation, much of the castle proper was stuffy, humid and dark; almost claustrophobic. The heat generated by the lights needed didn't help the situation and it was a somewhat humid day to start with. If I were to build one it would have better ventilation!

I mentioned earlier that the place was slap-dash in construction. It seems that whatever architectural items Mr. Hammond collected that could be embedded in cement met that exact fate. Plaques, reliefs, carvings, anything and everything was placed in the walls as the building went up. I think that some of the Medieval doors that were collected were simply hung on the walls and led nowhere; they may have been only decorative in nature. There were furnishings placed in front of them.

Some of the parts that really interested me were the Gothic architectural details. Many of them were poured cement, exactly what I'd like to do. Some of the trefoil windows, arches, and spiral staircases were all poured segments and not carved from solid stone; a few were just solid cement. The walls could easily be constructed in modern times using Castlemagic's method, slipform or a combination thereof. The building is huge, but not that huge, the Chateau living area I would guess at 2000 square feet. The castle is probably close to that as well. The great-hall alone is 65 x 28 (100' high) and just under 2000 square feet alone, not including the little side rooms.

It was really quite helpful to see the scale of the construction, even the little passages that were only 2 feet wide (I measured them). I can see already what I've overdesigned space-wise in the buildings I've done. With this castle nearby, I may have to make another visit and spend a whole day there with a surreptitious measuring tape.

At any rate, here are some of the pictures I've taken. Unfortunately, I don't have a wide angle lens so some of the shots don't really give the big picture, and also the lighting was poor so I did my best to not use a flash. That means I had to hold the camera very still or rest it on something; for the shots I wanted that wasn't always an option, so there may be some blur in the pics.

Monday, June 23, 2008

Sunday, June 22, 2008

Hammond Castle

I had the opportunity to visit Hammond Castle in Gloucester, MA today. It doesn't really fit into the site as far as modern, homebuilt, or efficient, but I found it very interesting and informative as far as scale, construction, and design goes. It was also just good fun to see the building and the imagination that went into it. While Hammond Castle lacks the long history and location in Old Europe, it's certainly cheaper and easier to get to than the castles across the pond! I can't believe that it's taken so long to get there, it's only 45 minutes drive from the house.

More photos and a better write up to come when I get time.

Wednesday, June 18, 2008

Comments

I originally started this post as a reply to the comments regarding the post below, but it got a little long winded so it now gets it's on spot on the front page.

Castle interiors were whitewashed, and were often painted with decorations to boot! Thanks for the reminder though, the structure would definitely be partly stone and partly "finished" interior.

You know, I've been to the Castlemagic site several times drooling over the really nice work that they do, and as I've advanced my construction knowledge I haven't stopped back by to look at the work going on in the pictures. Thanks for making me look again!

From what I can see, Castlemagic does a masonry stone wall, on the inside and outside, only one layer thick. In between the two there is a fairly large gap on the order of 8-12" that has re-bar and foam insulation in it. Once the masonry walls are set up, concrete is poured around the insulation to fill the gap. The stones are probably brought in, they border on quarry cut ashlar variety. They are very consistent as far as thickness and quality. This means they are very expensive but guarantees a good, consistent finished product. Looks good, works great. One could buy a mason's stonebreaker, hand pumped [image here], powered by air [image here] and fully powered hydraulic [here]. The first two are under $2000, the last is over $30,000. If one was willing to take the time to split stones, a very nice finish could be achieved. For $30,000 one could probably buy all the pre-split stones one would need for a reasonably sized building.

My issues are that I don't have the knowledge yet to appropriately design a masonry/cement wall for the height of the structure I'd like to build. I may very well be way out of line on my estimates for the structure I've been looking at because of that lack of knowledge. Also, the amount of concrete fill Castlemagic uses looks to be very large, ergo expensive. I'd like to minimize additional costs.

Here's a thought; why not use the slipform method or the method mentioned in the aforementioned book and build in a re-bar and insulation core?

A quick search of the internet reveals a really nice flash presentation of a pretty house done with slipform: House of Stone There are several sites that build using foam cores and a reinforced stone fascia, Hollowtop is a green building site that features this method in many places.

Overall, these methods seem to require more cement, but the build times are shorter and there's less stone to haul. I'll really have to work at finding out what type, quantity, strength and design of materials will be required to build something. Guess it all boils down to how much money is in the bank or how willing one is to haul lots of stone when it's time to build!

Castle interiors were whitewashed, and were often painted with decorations to boot! Thanks for the reminder though, the structure would definitely be partly stone and partly "finished" interior.

You know, I've been to the Castlemagic site several times drooling over the really nice work that they do, and as I've advanced my construction knowledge I haven't stopped back by to look at the work going on in the pictures. Thanks for making me look again!

From what I can see, Castlemagic does a masonry stone wall, on the inside and outside, only one layer thick. In between the two there is a fairly large gap on the order of 8-12" that has re-bar and foam insulation in it. Once the masonry walls are set up, concrete is poured around the insulation to fill the gap. The stones are probably brought in, they border on quarry cut ashlar variety. They are very consistent as far as thickness and quality. This means they are very expensive but guarantees a good, consistent finished product. Looks good, works great. One could buy a mason's stonebreaker, hand pumped [image here], powered by air [image here] and fully powered hydraulic [here]. The first two are under $2000, the last is over $30,000. If one was willing to take the time to split stones, a very nice finish could be achieved. For $30,000 one could probably buy all the pre-split stones one would need for a reasonably sized building.

My issues are that I don't have the knowledge yet to appropriately design a masonry/cement wall for the height of the structure I'd like to build. I may very well be way out of line on my estimates for the structure I've been looking at because of that lack of knowledge. Also, the amount of concrete fill Castlemagic uses looks to be very large, ergo expensive. I'd like to minimize additional costs.

Here's a thought; why not use the slipform method or the method mentioned in the aforementioned book and build in a re-bar and insulation core?

A quick search of the internet reveals a really nice flash presentation of a pretty house done with slipform: House of Stone There are several sites that build using foam cores and a reinforced stone fascia, Hollowtop is a green building site that features this method in many places.

Overall, these methods seem to require more cement, but the build times are shorter and there's less stone to haul. I'll really have to work at finding out what type, quantity, strength and design of materials will be required to build something. Guess it all boils down to how much money is in the bank or how willing one is to haul lots of stone when it's time to build!

Tuesday, June 17, 2008

Building ideas

After spending many hours reading and re-reading books like The Stonebuilder's Primer I've decided that the garage/barn will likely be the first built.

The reason this choice was made in the scenario using the buildings below is the size of the garage makes it livable and it has the least amount of stonework. I figure that the base can be constructed rapidly with stone to a point, and then the rest could be anything from steel I-beam supported to SIP walls. Likely SIP will be used for the upper half of the building because of the overhang, stone would be impractical and heavy not to mention never used in that fashion for a half-timber design.

I-Beams could be used to support the roof ridge beam and a more open floor plan. The lesser need for stonework would allow a "practice session", if you will, to learn to work with the material for the gatehouse and the large amount of stone needed for the main building. The main building's material is still up in the air... It would take hundreds of tons of stone to build it, and that leaves the problem of insulation. If I were to create a gap for insulation I could wind up increasing the wall thickness by 50% because it would render some of the wall non-structural. One could simply throw an insulated stick built shell inside, but what if you want a nice interior stone wall for decorative purposes as well as thermal mass? It's gonna be a lot of work!

The reason this choice was made in the scenario using the buildings below is the size of the garage makes it livable and it has the least amount of stonework. I figure that the base can be constructed rapidly with stone to a point, and then the rest could be anything from steel I-beam supported to SIP walls. Likely SIP will be used for the upper half of the building because of the overhang, stone would be impractical and heavy not to mention never used in that fashion for a half-timber design.

I-Beams could be used to support the roof ridge beam and a more open floor plan. The lesser need for stonework would allow a "practice session", if you will, to learn to work with the material for the gatehouse and the large amount of stone needed for the main building. The main building's material is still up in the air... It would take hundreds of tons of stone to build it, and that leaves the problem of insulation. If I were to create a gap for insulation I could wind up increasing the wall thickness by 50% because it would render some of the wall non-structural. One could simply throw an insulated stick built shell inside, but what if you want a nice interior stone wall for decorative purposes as well as thermal mass? It's gonna be a lot of work!

Saturday, June 7, 2008

Yep, still here...

I haven't made too many posts lately, but that isn't because I've given up on the ideas here. I'm actually still working on the design below; there are a few changes that I've needed to make in order to create a more buildable design, things like trying to arrange rooms requiring plumbing closer together so that long runs of potentially leaky pipes won't be required and can maintain a decent slope to the drains to keep waste flowing.

Also the positioning of load-bearing walls is having an effect on how the building's floor plan can be created. I realized that my positioning of the dining room knocks a substantial portion of structure out from under one of the main building's walls. Not good.

Also another concern is the span of the floor and the ability to frame it while avoiding building more stick-built load bearing walls and lolly-columns in the basement to support long floor joist spans. A solution could be the addition of steel beams midway across the floor to support shorter spans. That would require a cost calculation; would engineered spans cost more or less than steel beam supporting a normal joist setup? I'd like to maintain a completely open floor plan for the reason that walls can be positioned wherever necessary without having to redesign any load bearing walls and do major structural work in the event that remodeling is required. Don't like where a wall is? Need to create more rooms? Need to install an elevator for handicapped access? Just unscrew the walls from the floor, take them down and put new ones where you need them.

So many questions. I'm also trying to locate and calculate engineering data for the type of exterior walls I'm considering. I'd like to find out what quantity, quality and strength of material is required for this type of building. CMU, ICF, and stone, whether it be slipform or whatever, are all in the running. CMU would likely need to be filled with cement in certain areas plus the cost of the CMUs themselves, ICF is fantastic stuff but may be too expensive considering the height of the structure and the finishing required to have a non-styrofoam exterior and interior, and a solid rubble stone structure's walls may need to be more than 2 feet thick at the base to support a building like this if code even allows it. That's a lot of tonnage that one could smash fingers with, and a LOT of work that will take a long time compared to laying blocks of CMU.

Also the positioning of load-bearing walls is having an effect on how the building's floor plan can be created. I realized that my positioning of the dining room knocks a substantial portion of structure out from under one of the main building's walls. Not good.

Also another concern is the span of the floor and the ability to frame it while avoiding building more stick-built load bearing walls and lolly-columns in the basement to support long floor joist spans. A solution could be the addition of steel beams midway across the floor to support shorter spans. That would require a cost calculation; would engineered spans cost more or less than steel beam supporting a normal joist setup? I'd like to maintain a completely open floor plan for the reason that walls can be positioned wherever necessary without having to redesign any load bearing walls and do major structural work in the event that remodeling is required. Don't like where a wall is? Need to create more rooms? Need to install an elevator for handicapped access? Just unscrew the walls from the floor, take them down and put new ones where you need them.

So many questions. I'm also trying to locate and calculate engineering data for the type of exterior walls I'm considering. I'd like to find out what quantity, quality and strength of material is required for this type of building. CMU, ICF, and stone, whether it be slipform or whatever, are all in the running. CMU would likely need to be filled with cement in certain areas plus the cost of the CMUs themselves, ICF is fantastic stuff but may be too expensive considering the height of the structure and the finishing required to have a non-styrofoam exterior and interior, and a solid rubble stone structure's walls may need to be more than 2 feet thick at the base to support a building like this if code even allows it. That's a lot of tonnage that one could smash fingers with, and a LOT of work that will take a long time compared to laying blocks of CMU.

Subscribe to:

Comments (Atom)