Best wishes to everyone! Have a safe and happy holiday.

Busboom Castle is an owner built castle near Mahomet, IL.

Busboom Castle is an owner built castle near Mahomet, IL.

Perhaps the question most frequently asked of those who choose to build and live in a Castle is - “Why did you build a Castle?” Would that the response were as simple as - “It is so romantic and I’ve wanted to build one all my life!” But alas, the roots and reasons are much more complex.

The process began with a set of philosophical parameters that would form the framework around which the project would develop. These parameters included:

1) Both I and my companion chose early in life to follow life paths which were markedly non-mainstream. Our political, socioeconomic, humanitarian, cultural and global views are generated from within based on substantial life experience and are not mere reflections of the views “the system” cultivates for citizen consumption.

2) Both of us follow paths that frequently lead us inward through meditation, creativity and mind/body activities.

3) Both of us define our “success” through evaluators such as positive impact on others’ lives, giving more than we take, happiness, helping others define their life paths and reaching a point where we know that we need nothing more than our minds and hearts to survive and thrive anywhere.

4) The accumulation of material mass such as modern furniture, televisions, new cars, boats, techno-gadgets, appliances, picket fences etc. etc.. holds no draw over either one of us.

5) Both of us feel very much connected to all people on the planet and consider ourselves citizens of the planet rather than nationalistic units.

6) Both of us stand up for what we believe in.

7) Both of us strongly believe in self responsibility

8) Both of us believe that the attempt to homogenize society is destructive both to the individual and society.

With these existing philosophies, it was apparent immediately that we would not (COULD NOT) build the all American dream home - cape, ranch, saltbox, Colonial - at the end of a cul de sac in a regulated development where we had to ask what color paint we could use. To do so would effect a surrender of principle, a surrender of our vision, a surrender of belief.

BUT, this also created some problems. For this shared philosophy also surrendered any ability to operate in the world of “conventional” financing. But we would deal with that as the project developed.

With this philosophical foundation I started the design process. Our home would be a structure that reflected our shared philosophies. Our home must be a physical manifestation of our individuality, our conviction to cause and our resistance to forced or “suggested” mental and physical conformity. It must also bring joy and knowledge to others, be a gathering place for the sharing of friendship and ideas, cultivate creativity, reject disposable consumerism and strengthen our commitment to our chosen life paths. As medieval Castles had roots in taking a physical stand against the onslaught of aggressors, our Castle would also represent the stand we have taken against the onslaught of control, compliance and conformity.

One need not look any farther than the [lenders] banks to witness the long arm of conformity. Alternative home designs are looked at with the same warmth as was the black plague. So we decided to design the home WE wanted and build it out of pocket. In keeping with our philosophy, we would also do ALL the work ourselves. If a home is to truly be OUR home, it must come from OUR minds, OUR hearts and OUR hands.

After months of living on the land in a 20 foot trailer through the coldest snowiest winter on record, I developed a primary design that fulfilled the philosophical requirements above.

I could write endlessly on the process of product and materials choice but will try to focus it down a bit. We wanted the house to be as energy efficient as possible, as self sustaining as possible, as “eco-friendly” as possible and as true to our goal as possible. American building options tend towards gadgets, computer feedback, composites, and standard sizes and shapes. I soon ended up researching Swedish techniques and talking with many of their research scientists on the concept and science of home building. Subsequently, I opted for effective, non-technological, passive, nature sensitive, low maintenance building techniques.

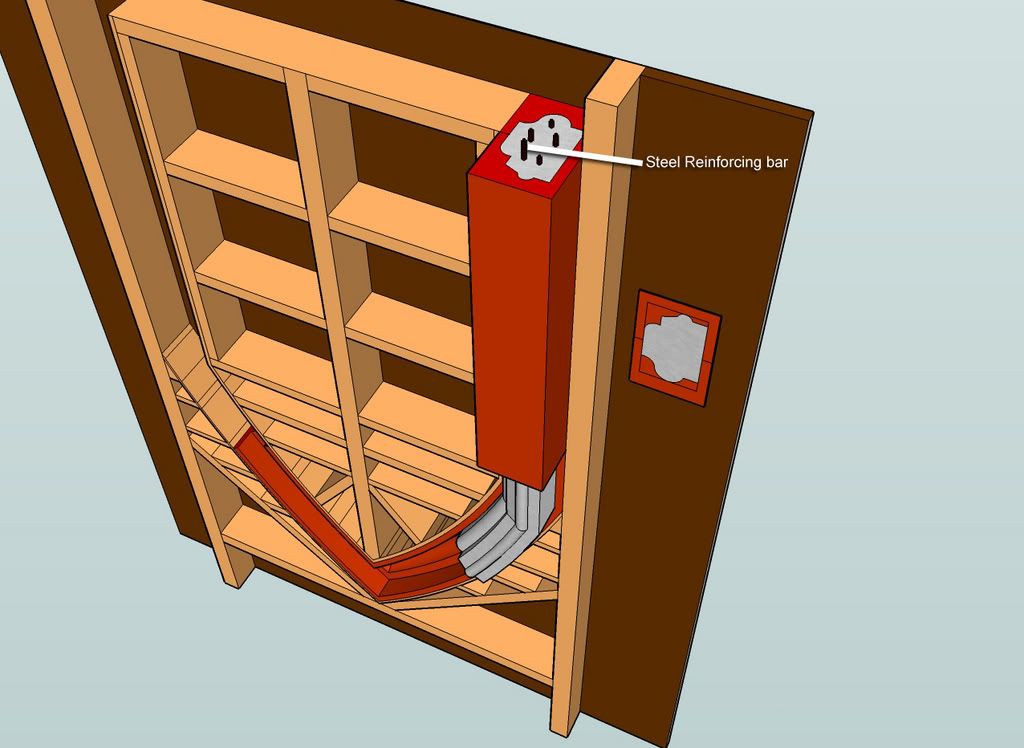

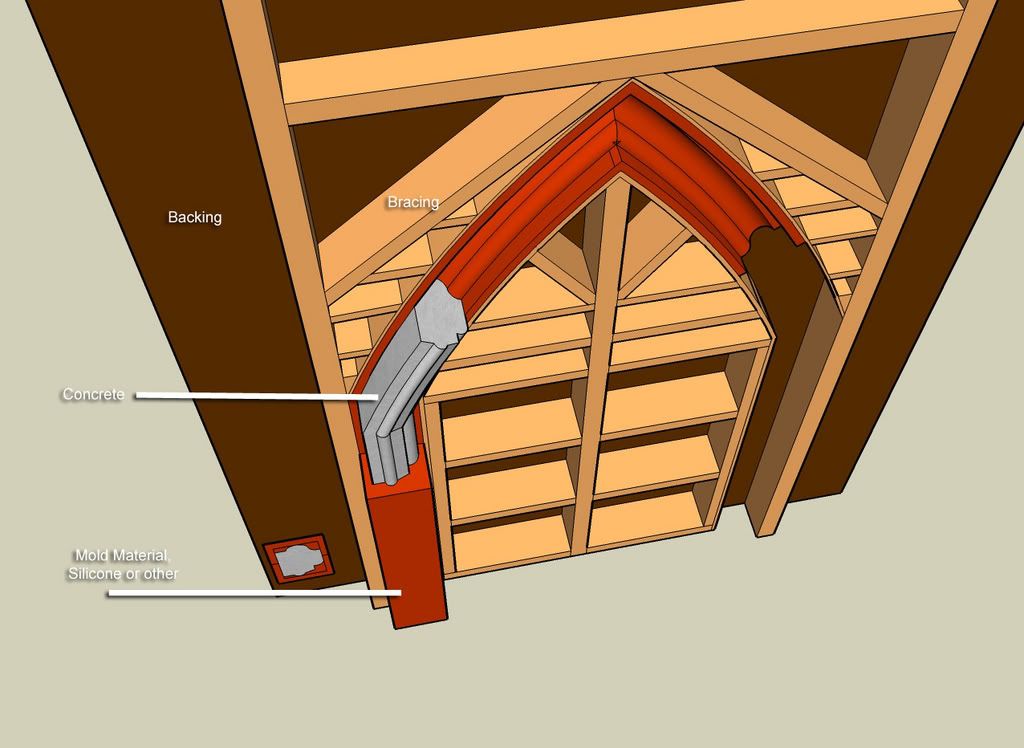

The decision as to what to build with was a major one. Stone was the obvious first reaction by most people. But, I do a lot of masonry and several red flags began waving. First, the time factor. There is no doubt that the best looking material for a Castle would be stone. But doing the exterior walls in structural stone would require literally years of work. We were living in a tent/trailer and could not envision the added years to get the structure even livable. Second, the use of stone requires a GREAT deal of additional structural preparation and materials which translates to much higher cost. Keep in mind that we are now building out of pocket on a limited budget. If money were not a serious problem we would NOT be living in a tent! After much research I settled on a concrete product. Concrete would fulfill the appearance requirements (even the old stone Castles were most often skim coated with a stucco like material), would be cost effective for us, and allow a reasonable time projection. The particular product was Sparfil 2...[I looked around for Sparfil for see if I could present an example or get more information about it. There is little information about it and no website for the company itself. Mr. O'Connor's description covers it pretty well, but from the information I could find, sparfil sounds like a similar material to Rastra Block, which is cement with recycled polystyrene in the mix]

This is a 12” thick by 8” high by 16” long block product. The body of the block is a mixture of concrete and insulating beads with 5 foam blocks filling 5 offset webs. Head ends are connected by insulating blocks. This gives a true, unbroken r25 wall. The blocks are dry stacked and troweled with surface bond cement. [Rob Roy mentions the use of dry stacking blocks and using a surface bonding cement in his book] . You can get some more structural info off of the Castle web site. The second floor ceiling has a Swedish vapor barrier and perimeter air gaskets. Above that is 16” of Canadian cellulose blown in insulation giving an effective r factor around r 80. The building is so well sealed that I have low volume (1/3 air change per hour) mechanical ventilation and make up air through a passive Swedish diaphragm tube.[This method of saving electricity is something some may be unwilling to pursue, or some methods may not be an option depending of the location of the site one would hope to build on; but they have done a marvelous job of proving that a castle need not cost a fortune to own and live in, and doesn't have to be a burden on the land around it or your pocketbook. It all depends on personal preference and what one is willing to do to reach their goal. Visiting the Castle's website, there also appear to be solar hot water heaters on the roof, an additional benefit to efficiency and savings.]

Your question as to concessions to “modern” techniques and amenities is indeed a good one. A GREAT deal of time went into this topic. Balancing off our desire to be totally self dependent and not “reliant” on the “system” for anything were some important considerations. We would be using the Castle for education - I am a gold and silversmith - I am a potter - I am a blacksmith - we would be doing shows, weddings, tours and banquets here - we want to live here forever (or however close to that as we can get!) - outhouses are not really good for the sensitive land we are on - there are going to be days when we don’t feel good - total “unplugging” from society was not necessarily our goal. So, we put in a drilled well. This gives us running water and flushing toilets in the house but we also put a hand pump on the well. We use this as much as possible to save energy and it makes us self reliant in the winter when snow and ice storms interrupt electric service. We heat with wood (we own 8 acres of wooded land) but put in an ultra efficient propane furnace as a back-up. If we are doing a wedding or tour and get home late, the two hour wait for the wood stove to heat the house up is not a practical option. The furnace has a sealed combustion chamber which uses outside air so it neither burns internal oxygen nor changes interior positive/negative pressure balances. The wood stove also has an outside air kit. We do have electricity which I need in my metal shops. But, all lights, switches and outlets are hidden in period decorations. Our hot water is electric which we only turn on every second or third day for about 30 minutes. Our monthly electric bill is only about $35.00 per month. We light primarily with beeswax candles in medieval reflector lamps.

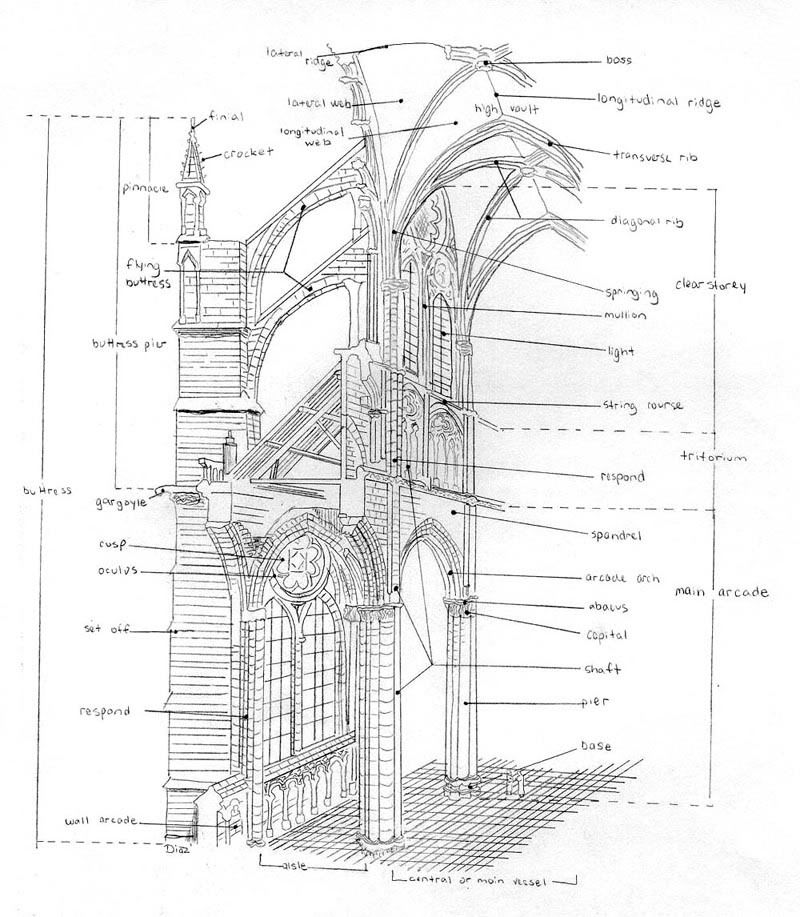

The outside appearance is Medieval Castle. In fact, it is becoming even more so as I now add stone accents, more battlements, iron work, a corner tower, palisades, monoliths, fire baskets, banners and stained glass. Inside is completely done in Medieval fashion. Tables, doors, cabinets, window trims, toilet area, bathing area and beams are all made with salvaged 300 year old lumber. The upper floor is one room with a large banquet table (300 year old wood and seats 25 plus) and our canopied bed. This is true to early Medieval custom. Guests sleep on the floor as knights and travelers did. We heat with wood which means the lower level is nice and warm. On cold nights we can feel the coolness in the air upstairs. The bed has great drapes which we close against the cold at night. We step into the cool air in the morning and feel the physical connection with the winter air outside. We usually wear period clothing around the Castle. Even the toilet is enclosed with antique lumber to look like the lieu in a medieval keep.

The Castle has a lot of our intellect, blood, sweat and tears within its walls. It tested my mental , physical and emotional limits. 4 out of every 5 couples who undertake building a “modern” home together break up. [Visiting the owner-builder book website I came across a thread discussing the effects of building your own home on some relationships. For that particular site it wasn't 80%, but owner-builders indicated that it certainly ended some relationships.] It has brought my companion and me even closer than we were. The name of the Castle is Castle Anam Cara which means soul mate. It was the only name which seemed appropriate. The Castle is an island in a sea of oatmeal. It is a time machine transporting one to a time when people were far more connected to each other and to the flow of nature. It is a gate which opens inward. It is the manifestation of the Irish warrior call - Bona na Croin. Neither collar nor crown - We serve no master and bow to no man. It is our beautiful home.